TECHNOLOGY

TECHNOLOGY

EXCELLENT QUALITY BY PATENTED TECHNOLOGY

EXCELLENT QUALITY BY PATENTED TECHNOLOGY

TC TECH’s system is suited for processing of plastics, where diffusers for mini LED and LGPs are some of several areas of application.

TC TECH makes it possible to produce double-sided patterns with nano scale features in ultra-thin plastic films at a high production rate. The technology is ideally suited for applications where excellent replication and complex patterns are a requirement.

Light guide films, mini LED diffusers and microfluidics diagnostics assays are some of applications which the TC TECH system is used in today.

PRECISE CONTROL

PRECISE CONTROL

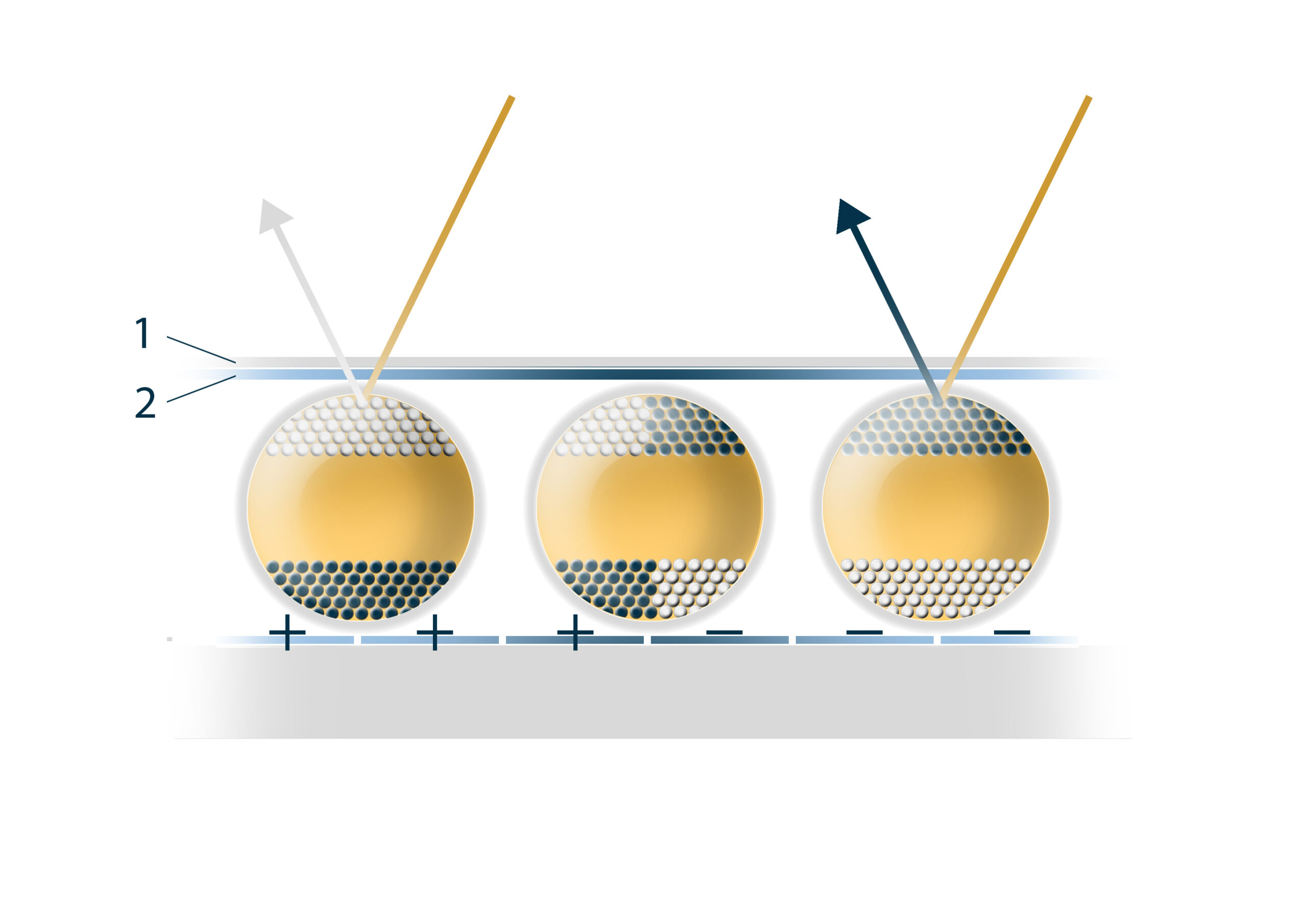

During production, a plastic film is pressed between two induction units with replaceable stampers, with a pattern which will be transferred to the film. In the process, the plastic is heated in a few seconds up to the desired temperature (usually about 200° C) whereby the plastic becomes soft and the pattern is transferred. Immediately afterwards, the plastic film is cooled fast down to room temperature.

With our rapid and smooth heating process, it is possible to replicate advanced patterns down to nano-level. This exact heating process, in combination with rapid cooling, ascertains that the plastic material is never overheated.

As a result, the substrate and final product will be free of common defects such as brittleness, stress and birefringence.

MANUFACTURING WITH CLEAR ADVANTAGES

MANUFACTURING WITH CLEAR ADVANTAGES

Mini LED backlit LCDs are an emerging high quality display technology competing with OLED. Mini LED is currently used by Apple in some flagship products.

The display uses a large array of small LEDs instead of a LED strip to illuminate the LCD panel. To distribute the light one or more diffusers is used.

- These need to be as thin as possible and have a high resolution pattern, potentially double sided.

- By embossing a monomaterial film it is possible make thin diffusers (down to 0.1mm).

- The double sided high resolution patterning makes it possible to with precision pattern both sides.

- The TCP System could be a method to reduce the number of diffusers need while also reducing the thickness of each layer.

No other production equipment can meet all these requirements.

Front Light for e-readers is an application in where TCP System have an edge.

Front Lights are placed at the front of the display and is use to illuminate the e-Ink display in an e-reader. (1)

- This increases requirements on resolution in the pattern and on UV resistance in the material

- The monomaterial used in the TCP System has a natural high UV resistance.

- The unique embossing process in the TCP System can replicate the high resolution patterns required.

No other production equipment can meet all these requirements.

REDUCE ENERGY CONSUMPTIONS IN DISPLAYS

REDUCE ENERGY CONSUMPTIONS IN DISPLAYS

For manufacturers of screens and manufacturers of the final product, TC TECH’s production method means the following advantages:

- A perfect nano pattern reflects and controls the light and provides better contrast. Heat emission is reduced as most of the light ends up correctly.

- The effect on the light source can be reduced while maintaining the brightness of the display, which contributes to reduced energy consumption.

- It is possible to use thinner diffusers, LGP or any other optical film, which reduces the thickness and weight of the screen.