Following requests from customers who manufacture optical films, including Light Guide Plates (LGP’s) to laptops, TC TECH has successfully extended the maximal pressure surface of the system to 370×235 mm so that it can handle surfaces up to 17-inch displays.

The new T10 tool has been evaluated at TC TECH’s facilities with excellent results and became available to order in late September.

With the new tool upgrade, TC TECH’s production system can manufacture optical films for the three most popular laptop display sizes: 13, 15 and 17 inches. This can be compared to the previous T6 tool that can handle optical films for display sizes up to 15 inches. The new tool is compatible with all of TC TECH’s production systems and can be easily installed at the customer’s facilities.

TC TECH is now also offering its production system with the new tool in its ongoing sales processes, which makes the company’s offer even more attractive than before.

“I am very pleased that our team has been able to upgrade one of the most important parameters of our production system so that it covers all of the leading display formats for laptops. This upgrade is a testament to the versatility and flexibility of our system, which is an argument that we often highlight in our sales processes,” says TC TECH’s CEO Alexander Luiga.

TC TECH has developed a new material for high-resolution matrices in collaboration with the Taiwanese electroforming company Hui Fong

By using extremely detailed matrices manufactured in the new material, customers will be able to utilise the capabilities of TC TECH’s production system to a maximum.

Matrices are thin plates that contain the structures to be embossed into thin plastic details, and they are usually manufactured in pure nickel. For simpler and slightly more advanced matrices this has been fully adequate, but to be able to fully utilise the capabilities of TC TECH’s production system, matrices with a corresponding quality and resolution are needed.

The new material is a nickel alloy with a high concentration of cobalt that is suitable for making matrices with even finer patterning compared to what was previously possible. Huifong, a Taiwan-based company focusing on nickel-cobalt electroforming, was TC TECH’s collaboration partner during the development of the new material.

“Our production system can be compared to the latest 8K TV sets, while traditional nickel matrices that constitute the moulds for what the system prints (or play in this analogy) cannot handle more than 4K resolution, and even that is a stretch, without introducing noise in the picture. We have basically been a little ahead of our time. By creating this new material, we have been able to upgrade another important part of the production chain for the manufacturing of very thin and detailed plastic details to the same high standard as our system,” says TC TECH’s CTO Jan Jäderberg.

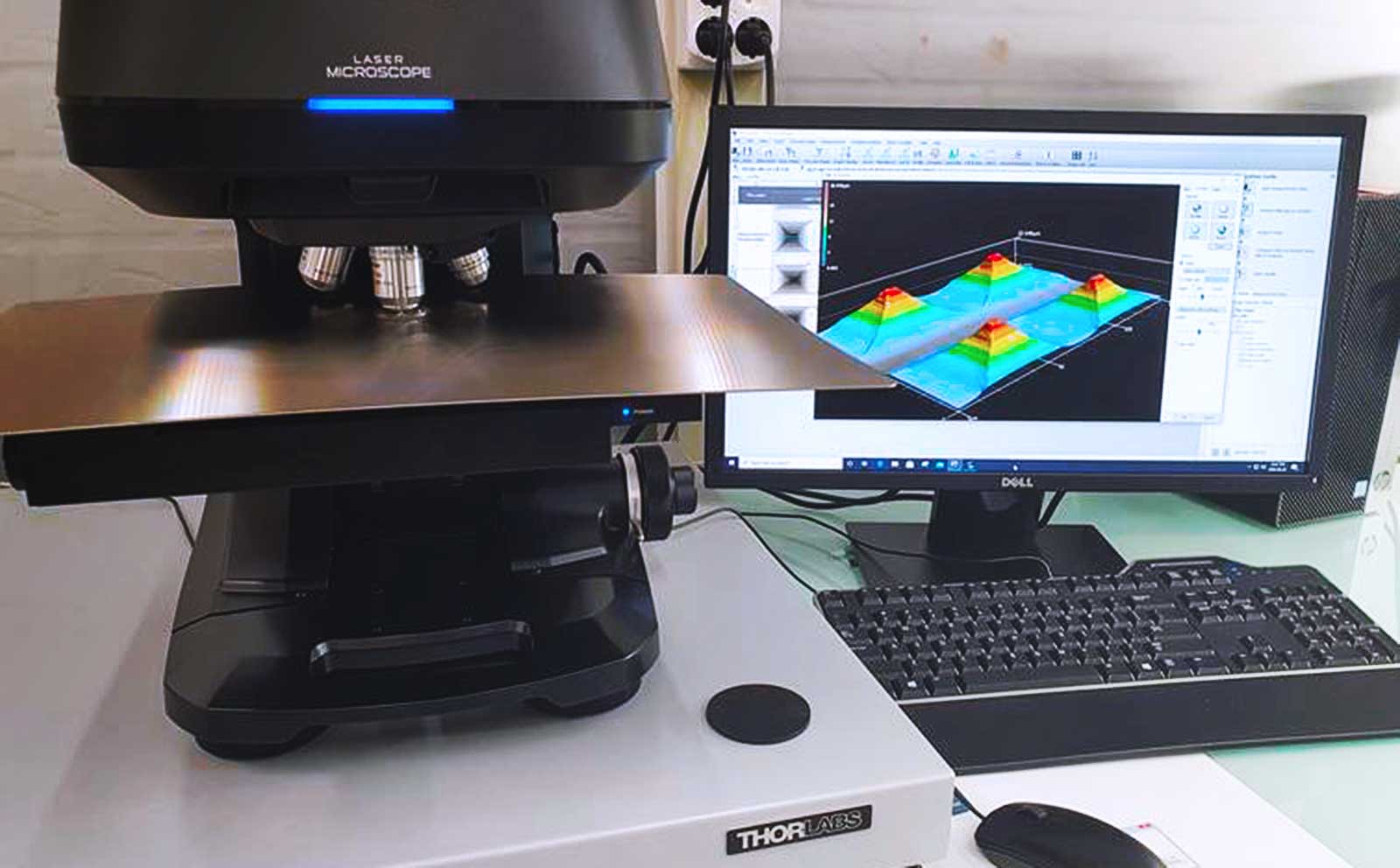

Every step in the manufacturing of matrices in the new material has been chemically validated and mechanically validated in electron microscope at TC TECH’s facilities and at a Taiwan-based customer’s facilities. The customer has then approved the new material.

“It will be exciting to see what can be achieved now that we unlock more of the potential in our production system. There is a demand for matrices with extremely high resolution in several application areas, not least when it comes to light diffusers for mini and micro LED displays,” says TC TECH’s CEO Alexander Luiga.

Get to know TC TECH: Interview with Tintin Chien, Sales & Product Manager focusing on international B2B development

Every TC TECH employee has a unique skill set and background that contributes to the creation of a dynamic and well-functioning team. In this newsletter Tintin Chien, Sales & Product Manager focusing on international B2B development, talks about her view on the company’s sales process and possibilities for the future.

Can you tell us briefly about your educational and professional background, and your position at TC TECH?

“I have a master’s degree in Material Science and Engineering from NTHU, Taiwan. Previously, I worked with development and project management in the solar energy sector for eight years in Asia and Europe. Then I started working for TC TECH, and I have been with the company the last four years. At first, I worked as a system engineer, but today I am Head of Sales for Asia where China and Taiwan are our main markets.

My position includes:

- Head of customer communication

- Business development and building customer relations

- Meeting potential customers on location for technical discussions

- Finding new potential applications in various industry segments

- Managing and training our local distributors

What do you like the most about your work at TC TECH?

”The new technologies and interesting products that TC TECH offers have very high potential in many different industry applications. Among other things, they enable the production of higher quality LPG’s and other optical films that go beyond the current industry standard.”

”The biggest and most exciting challenge is to enter into an already established market with a new production method that sets a new industry standard. By working closely with every customer, we are able to set a new standard in precision and quality together, creating a win-win situation.”

Which application areas and geographic markets are you focusing on when it comes to marketing and sales activities?

”Our systems are well suited for ambitious customers that create products with high-performance specifications. We are focusing on customers aiming to reach leading performance in LGP’s, diffusers for mini LED and other optical films with very detailed patterning.

“Providers that manufacture optical LPG products of the highest quality are based in China and Taiwan, and we have therefore decided to focus on these countries. To broaden our application areas, we are now evaluating other potential markets and applications where TC TECH’s unique technology can be utilised.”

Can you briefly describe the interest you are receiving from potential customers in these new application areas?

“The traditional production methods used today are not good enough for next-generation products in several areas where very high precision and quality is required.

TC TECH’s technologies enable manufacturing of future products in areas such as:

– Micro and mini LED

– Optical films for AR and VR applications

– Films for lightings

– Microfluid applications in the biotechnology sector

About Tintin Chien

- Education – Master’s degree in Material Science and Engineering

- Background – Born and raised in Taiwan, lives in Sweden since 2010

- Languages – Mandarin, Taiwanese, English and Swedish

- Personal interests: Triathlon (swimming, cycling, and running), hiking and enjoys most endurance sports. Completed a Swedish Classic in 2017 (completion of four classic Swedish endurance events in one year) and Ironman Kalmar in 2018. Trains regularly with the Stockholm City Triathlon Club.