This enables the customer to manufacture optical films for the three most popular laptop display sizes: 13, 15 and 17 inches.

The rapid upgrade to the new T10 tool, which became available to order in late September, shows that the increased functionality of the new tool has been anticipated.

– Our technology will enable this customer to develop innovative solutions for displays, with possible benefits such as improved picture quality and reduced energy consumption, and offer them for integration in, for example, a wide range of laptop displays in different sizes. This will make the technology more attractive throughout the design and manufacturing chain. Over time, we thus expect that the T10 tool will generate more orders for our production systems, says TC TECH’s CEO Alexander Luiga.

In addition to the above-mentioned customer in Taiwan, other TC TECH customers and potential customers have also shown interest in the new T10 tool. The tool is now included as an integral part of the production systems offered in future sales processes.

TC TECH stations Sales & Product Manager in Taiwan

Due to lower spreading of infection and reduced restrictions in Taiwan, TC TECH is now able to reinstate some of its efforts to develop customer relations and sales processes on site in Asia.

It is Tintin Chien, Sales & Product Manager with a focus on international B2B development, who is now stationed in Taiwan to represent TC TECH. She has recently begun working after completing the obligatory two-week quarantine upon arrival. Tintin will be on site in Taiwan from time to time, initially until the Christmas holidays, to maximize her stays considering the quarantine regulations.

”It is positive that we are now able to reinstate a more normal way of doing business in one of our most important markets. We see great potential in further developing our relations with both existing and new customers. Among other things, we will stay in touch with the customer in Taiwan that recently upgraded one of their production systems with our new T10 tool,” says TC TECH’s CEO Alexander Luiga.

More information on Tintin Chien can be found in the October issue of TC TECH’s newsletter, in which she is featured in a short presentation and interview.

The production system delivered to Nicrotek in China has now achieved final approval by the customer

Following delays due to Covid-19 related travel restrictions, technical personnel from TC TECH were finally able to be on site in China in November to complete the installation.

Nicrotek is a Chinese manufacturer of advanced LGPs in the premium segment for both Chinese and international manufacturers of LCD displays. Following the final approval, the customer has started using the system for the production of LGPs.

“It is exciting that this customer is now finally able to use our production system to manufacture advanced LGPs. We look forward to following how they will take advantage of the benefits that our technology brings to the table,” says TC TECH’s CEO Alexander Luiga.

Due to the Covid-19 pandemic, China has put strict regulations in place to limit travelling into the country. This means that visas are only granted for specific purposes that benefits Chinese activities. In this case, Nicrotek was able to state that the trip was a necessary step in their process to start using new technology provided by TC TECH.

Get to know TC TECH: Interview with Stefan Strandberg, in charge of production

All of TC TECH’s employees have a unique competence profile and background that contribute to creating a dynamic and well-functioning team. In this newsletter, Stefan Strandberg, in charge of production, is interviewed on his company role.

Can you tell us briefly about your professional background, and your position at TC TECH?

“Most recently before I joined TC TECH, I worked with servicing and development of CD, DVD and solar energy products, including being involved in starting up a new factory in Thailand. I am a bit of an all-rounder in my field. Among other things, I have worked with sales and servicing in engineering as well as marine industries.”

“I have worked for seven years at TC TECH with various tasks over the years. Currently, I am in charge of the production of our production systems and tools.”

My position includes:

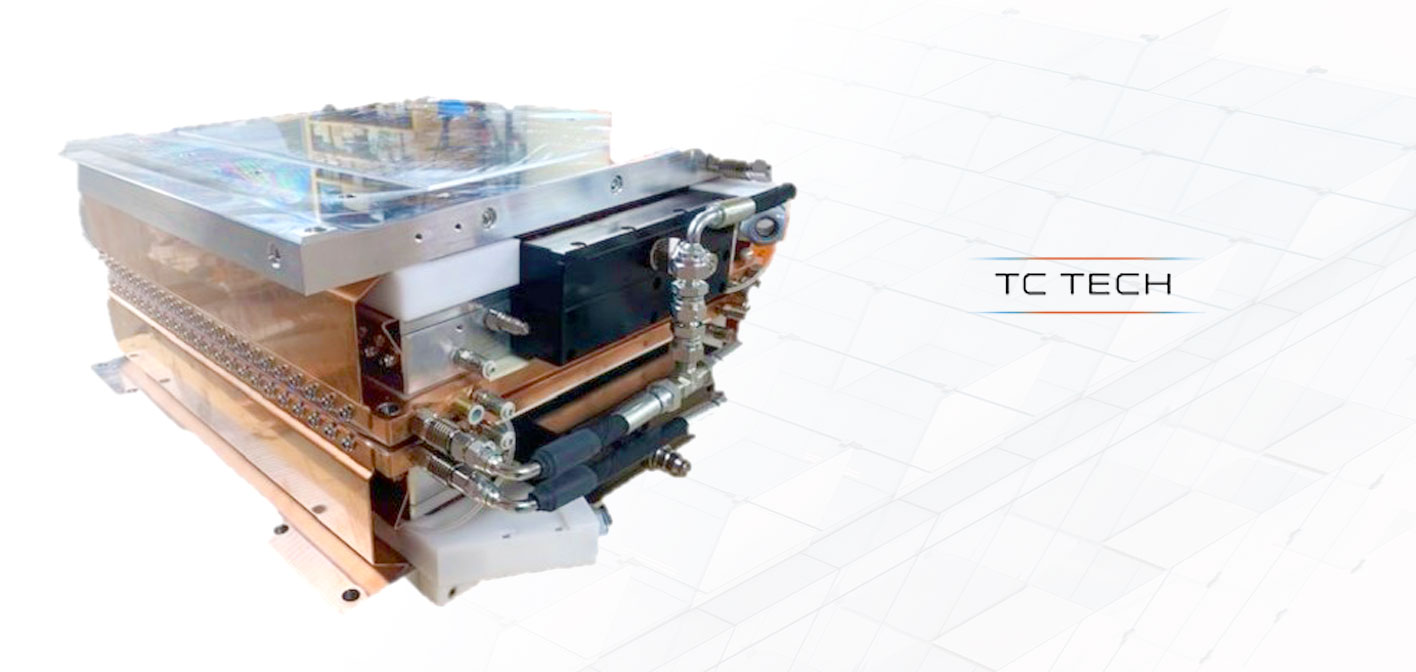

- Provide our subcontractors and contract manufacturers with the appropriate documentation and knowledge needed for manufacturing components and assembling our TCP 150 production system

- Educate/train subcontractors and contract manufacturers

- Assemble our tools T6 and T10

- Participate in the work of developing the production system, the tools used and accessories

- Prototype production

- Testing of prototypes and different production solutions

- Responsibility for manufacturing documentation

- Responsible for the pneumatics and hydraulics field

What do you like best about your work at TC TECH?

“I have always worked with product development and was attracted by the fact that TC TECH is a company that works with new technology. It is a company where you are given the opportunity to participate in several different areas, such as development and production management, which suits me well considering my broad background and interest in finding new effective solutions to complex problems.”

Do you have any special interests that you pursue when not working?

“I enjoy boating and working on my house in the countryside. There is always something that needs to be done!”